UPM Pharmaceuticals is an award winning CDMO that specializes in delivering high-quality oral solid dosage manufacturing services tailored to the unique needs of our clients. With decades of expertise and cutting-edge technology, we offer a full range of solutions for solid oral dosage forms, including modified-release formulations, immediate-release tablets, and more. Our flexible infrastructure supports projects from small R&D batches to large-scale commercial production, ensuring efficiency and precision at every stage. With our strict regulatory compliance and a client-focused approach, UPM provides customized solutions to meet your unique solid dose manufacturing & handling challenges. Partner with us for reliable, scalable, and innovative oral solid dose manufacturing.

Oral Solid Dose Manufacturing and Handling

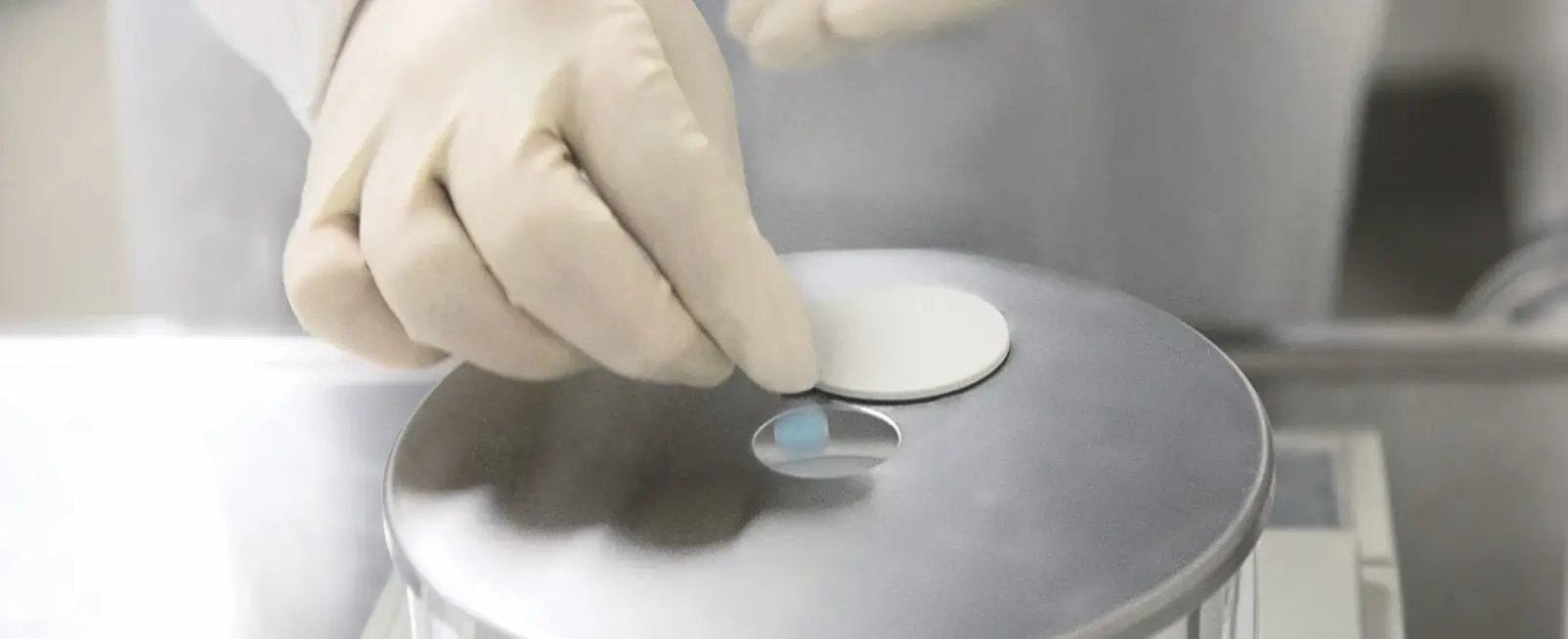

cGMP Oral Solid Dosage Manufacturing of Tablets & Capsules

From efficiency-enhancing technologies for clinical trial supply to scalable mechanisms for commercial production, UPM Pharmaceuticals has the flexible infrastructure and expertise to support our customers across all stages of oral solid dosage manufacturing, including formulation, development, and packaging.

Why Choose UPM Pharmaceuticals for Oral Solid Dosage Manufacturing?

At UPM Pharmaceuticals, we take pride in being a trusted partner for oral solid dosage manufacturing services for all of our projects. Here's what sets us apart:

- Extensive Expertise: Decades of experience allow us to handle complex oral solid dosage forms and specialized delivery systems with precision.

- State-of-the-Art Facilities: Advanced equipment and flexible infrastructure enable efficient production, from clinical trial supply to commercial scale manufacturing.

- Customized Solutions: We offer personalized support throughout the drug development and manufacturing process to meet your specific needs.

- Regulatory Excellence: Our robust quality systems ensure compliance with cGMP standards and facilitate a seamless path to market.

Industry Leading Oral Solid Dose Manufacturing

UPM Pharmaceuticals has extensive experience in the development and manufacturing of solid oral dosage forms, including modified-release formulations and immediate-release tablets, from clinical to commercial scale. Our state-of-the-art equipment, combined with our longstanding in-house expertise, provides our customers with the highest quality solid oral dosage form through the most efficient processes.

Whether you're running a small R&D batch or producing at commercial scale, UPM can seamlessly provide tailored solid dosage form solutions. With the capacity to produce from 100 to over 100,000 tablets or capsules per hour—and up to 4 billion units annually on a single shift—UPM is equipped to handle oral solid dose manufacturing projects of all sizes.

Our Oral Solid Dosage Capabilities

- Blending

- High-Shear and Fluid-Bed Granulation

- Variable Capacity High-Speed Coating

- Wurster Coating

- Extrusion-Spheronization

- Roller Compaction

- Bi-layer Compression

- Fluid Coated Beads, Pellets, Granules and Crystals

- Precision Processing of Fine Powders, Pellets, Granules and Crystals

- Production of High-Density, Low-Excipient Granules

- Uniform, Durable Compaction

- Mini-Tablets and Bi-Layer Tablets

- Encapsulated Tablets and Beads

- Immediate-Release Tablet and Capsule Formulations

- Modified-Release Tablets and Capsule Formulations

- Modified-Release and Cosmetic Tablet Coating

- High-Dose Capsule and Tablet Formulation

Make UPM Your Partner in Oral Solid Dosage Manufacturing Today

Whether you’re in the early stages of development or require reliable pharmaceutical contract manufacturing at commercial scale, UPM Pharmaceuticals is here to help. Our team’s expertise in oral solid dosage manufacturing, combined with cutting-edge technology and a commitment to quality, makes us the ideal choice for your project. Contact us today to learn how we can accelerate your journey to success.

Contact UPM Pharmaceuticals